Documents

Product-specific data sheets and operating instructions can be found in our download centre.

downloadQuality that pays off for you

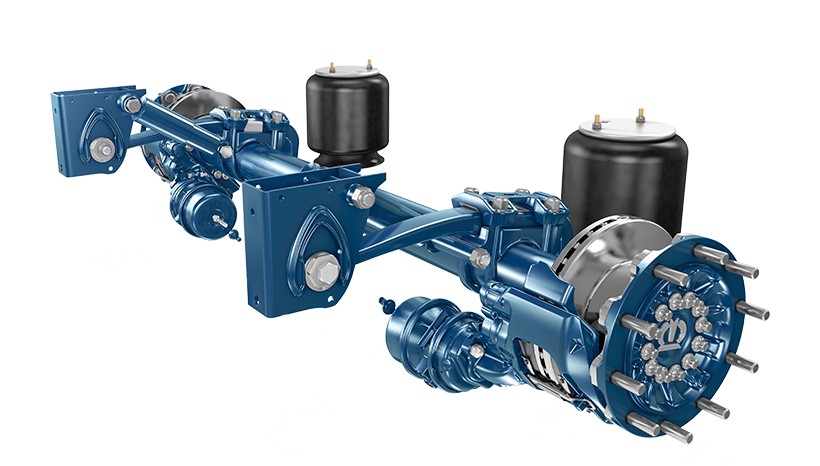

Highest flexibility thanks to the diverse variants - Along with the proven disc brake, KRONE Trailer Axles are now also available in a smaller 377 x 45 mm version. In addition to the piggyback version for rail loading, KRONE also offers other variants. This means that your trailer can be optimally equipped to meet your everyday transport requirements.

Superior in any concern.

Advantages at a glance

Always a plus on equipment.

Documents

Product-specific data sheets and operating instructions can be found in our download centre.

download

How can I help?